Hammerhead Swing Arm

CLICKER PRESSES

HAMMERHEAD Swing-Arm Clicker Press – Precision, Efficiency, and Ease.

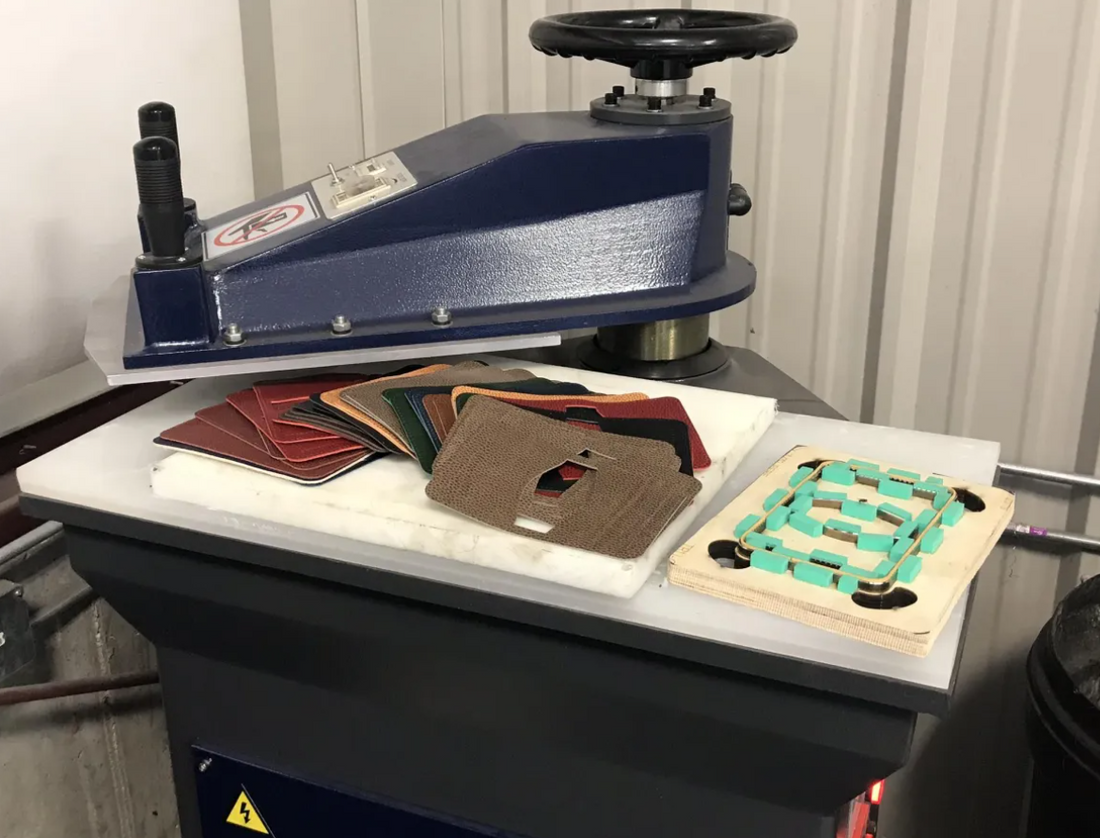

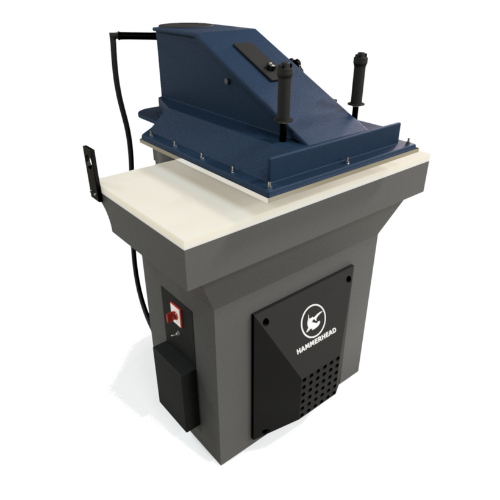

The HAMMERHEAD Swing-Arm Clicker Press is the go-to choice for precision die cutting, offering efficiency, durability, and ease of use. This Clicker Press is built for fast, accurate cuts, making it the ideal first step into moderate levels of die cutting production. The swing-away arm (head) allows for easy die alignment and material positioning, reducing waste and maximizing productivity.

These features make the HAMMERHEAD Swing-Arm Clicker Presses the preferred choice for cutting leather, foam, rubber, composites, nonwovens, textiles, plastics, and many other materials. This Clicker Press is also commonly used to produce samples for carpets, textiles, roofing and other construction supplies, cabinetry veneer and facades, and much more.

SA SERIES

Shop this series→SB SERIES

Shop this series→Reliability

HAMMERHEAD Clicker Presses deliver reliable performance with unmatched flexibility. HAMMERHEAD Swing-Arm Clicker Presses feature upgraded seals, enhanced controls, and customizable power configurations. Designed for versatility, these Industrial Clicker Presses support single-phase and three-phase power, including 110V, 220V, and 480V options. With the ability to operate on a 15A breaker, they are perfect for home workshops, small-scale manufacturing, and light industrial die cutting applications.

Engineering

HAMMERHEAD machinery is continuously tested, upgraded, and redesigned to deliver exceptional reliability and user-friendly operation. Each machine is engineered for effortless maintenance, compliance flexibility, and long-term performance, featuring:

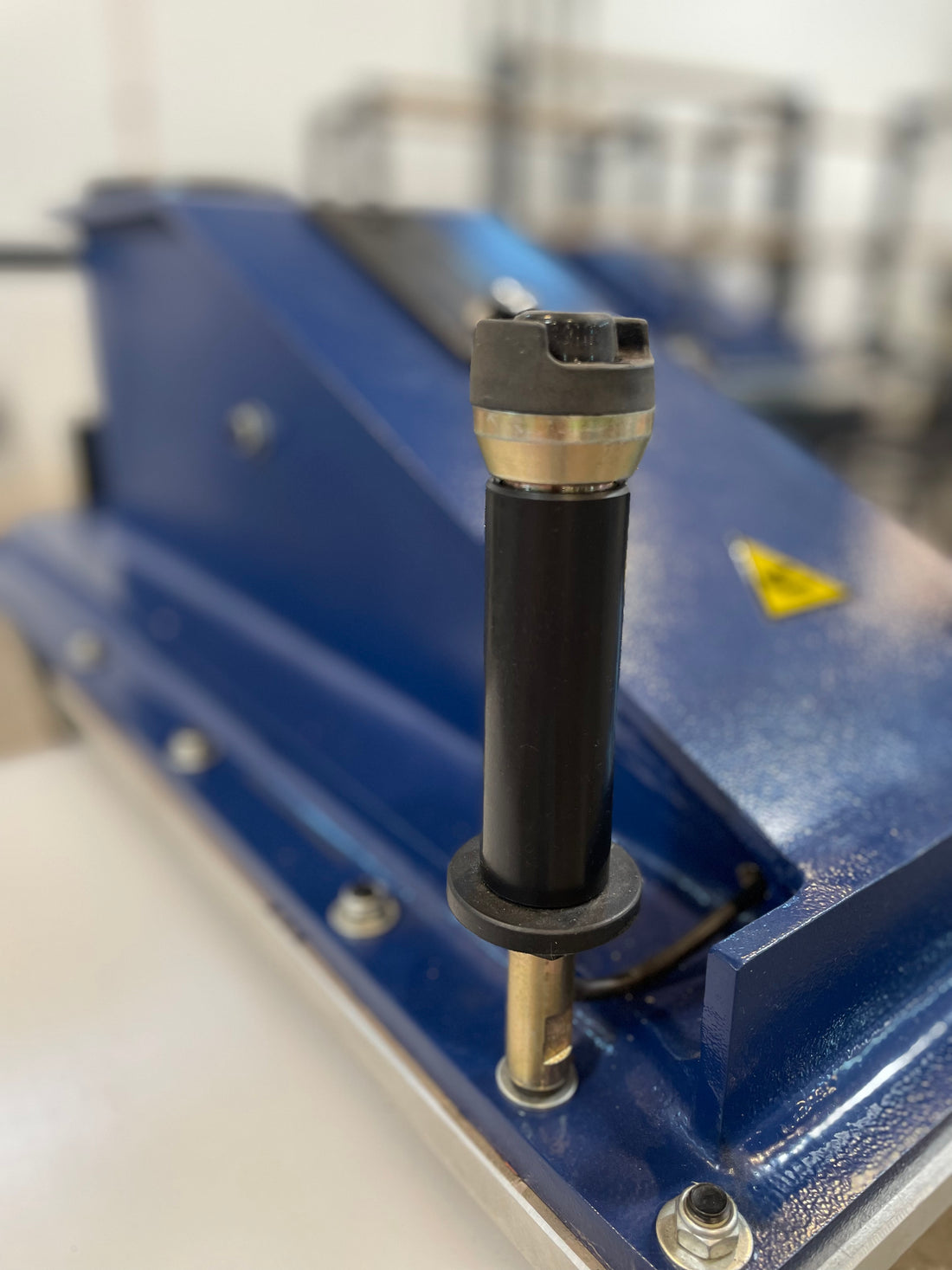

✔ JIC Fittings for Easy Maintenance – All metric fittings have been replaced with JIC fittings, simplifying repairs and part replacements.

✔ UL 508(a) Compliant Design – Panels are built following industry best practices, with the option to include fully UL 508(a) certified panels if required.

✔ Power & Overload Protection – Integrated safety systems help ensure consistent performance and equipment longevity.

✔ ETL & UL 508(a) Certification Options – Machines can be configured to meet Nationally Recognized Testing Laboratory (NRTL) standards, ensuring compliance with stringent safety and performance regulations when needed.

Skip the delays of qualification and validation—with HAMMERHEAD, you get production-ready equipment, designed to meet your specific compliance and operational needs from day one.

Comprehensive Support and Maintenance Programs

At Hammerhead Industrial, we stand behind our products with comprehensive support and maintenance services tailored to your needs. Every new HAMMERHEAD Swing-Arm Clicker Press comes with a standard one-year warranty, ensuring reliable performance and peace of mind. Need extended protection? Optional extended warranty plans are available for continued coverage.

Our expert team provides installation assistance, routine maintenance, and on-demand troubleshooting to keep your swing-arm press operating at peak efficiency. With rapid response times and dedicated service, we help minimize downtime and keep your operations running smoothly and efficiently.

Common Terminology

Swing-arm Clicker Presses are known by many names across various industries, reflecting their versatility across many cutting applications. Let's make sure we clear up some common terminology.

✔ Swing-Arm Clicker Press – The most widely used term for this press, featuring a pivoting or swinging head for easy table access and die placement.

✔ Clicker Press – A general term for hydraulic die-cutting machines, commonly used in leatherworking and soft material cutting and most often refers to this type of machine. Coined for the "clicking" sound it makes when making a cut compression.

✔ Swing-Head Press – Highlights the swiveling motion of the cutting head, allowing for effortless material handling.

✔ Swing Beam Press – Sometimes used interchangeably with Swing-Arm Press, but is generally becoming outdated terminology.

✔ Hydraulic Clicker Press – Emphasizes the hydraulic power system, but is the same type of press.

✔ Manual Clicker Press – Refers to hand-operated versions, ideal for small-scale operations like leather working, but is not the same as a Swing-Arm Clicker Press.

✔ Leather Clicker Press – A specialized term used in leatherworking and footwear industries, but the same type of machine as a Swing-Arm Clicker Press.

✔ Fabric Cutting Press – Used in textile and upholstery industries where precision die-cutting is required. Depending on the use, it may or may not be referencing a Swing-Arm Clicker Press.

✔ Swing Arm Die Cutter – Highlights its primary function of die cutting for various materials, but is the same as a Swing-Arm Clicker Press.

✔ Industrial Clicker Press – A broader term referring to heavy-duty models designed for high-volume production, but is most commonly referring to a Swing-Arm Clicker Press.

Whatever the name, HAMMERHEAD Swing-Arm Clicker Presses are engineered for reliability, precision, and efficiency, making them the preferred choice for die-cutting professionals across these industries.

Automation and Upgrades

We know that not all companies have the budget for large-scale automation, so we are doing our best to build automated systems around Clicker Presses to provide a "foot-in-the-door" automation option to smaller companies. Ask us about these clicker press automation packages we're working on:

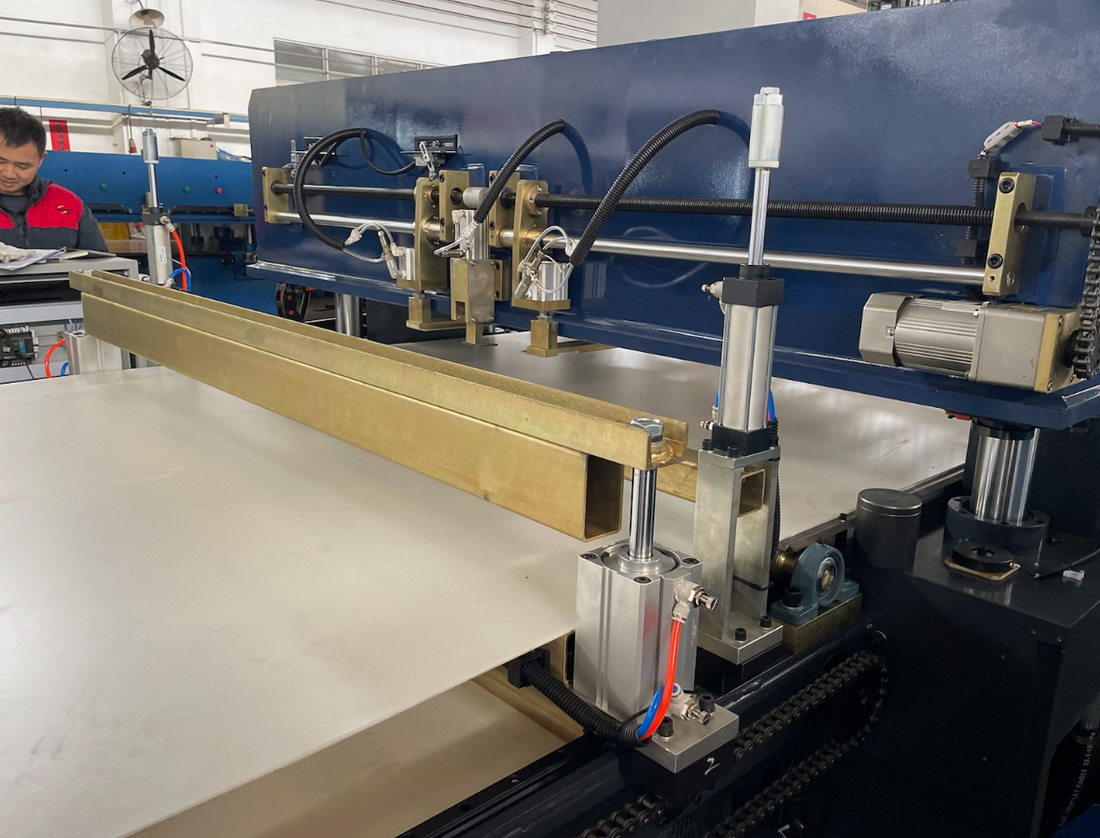

- Automatic Sliding Table: Designed for sheet material, this feature enables automatic advancement and cutting, streamlining the workflow and increasing efficiency.

- In-Out Roll Feed: Ideal for roll material, this option allows for automatic advancement, cutting, and rewinding, optimizing the processing of continuous materials.

- Automatic Swing-Away: This mechanism automatically swings the cutting head out of the way after a cut, reducing operator fatigue and enhancing productivity.

- Encoder Set Cutting: This feature uses an encoder to precisely set and save cutting positions for different applications, allowing for easy recall and consistent results across various tasks.

- Fully Electric Swing Arms: This option will be piloted in 2025 and available shortly after for purchase. We are engineering a fully electric version of a Clicker Press that is servo driven to accommodate the needs of many clean room applications. It will likely have some of the other features already built in, like the automatic swing away, and encoder set cutting functions.

The HAMMERHEAD Swing-Arm

GET A QUOTE

We offer free, no-pressure consultations and we typically respond within 24 hours.