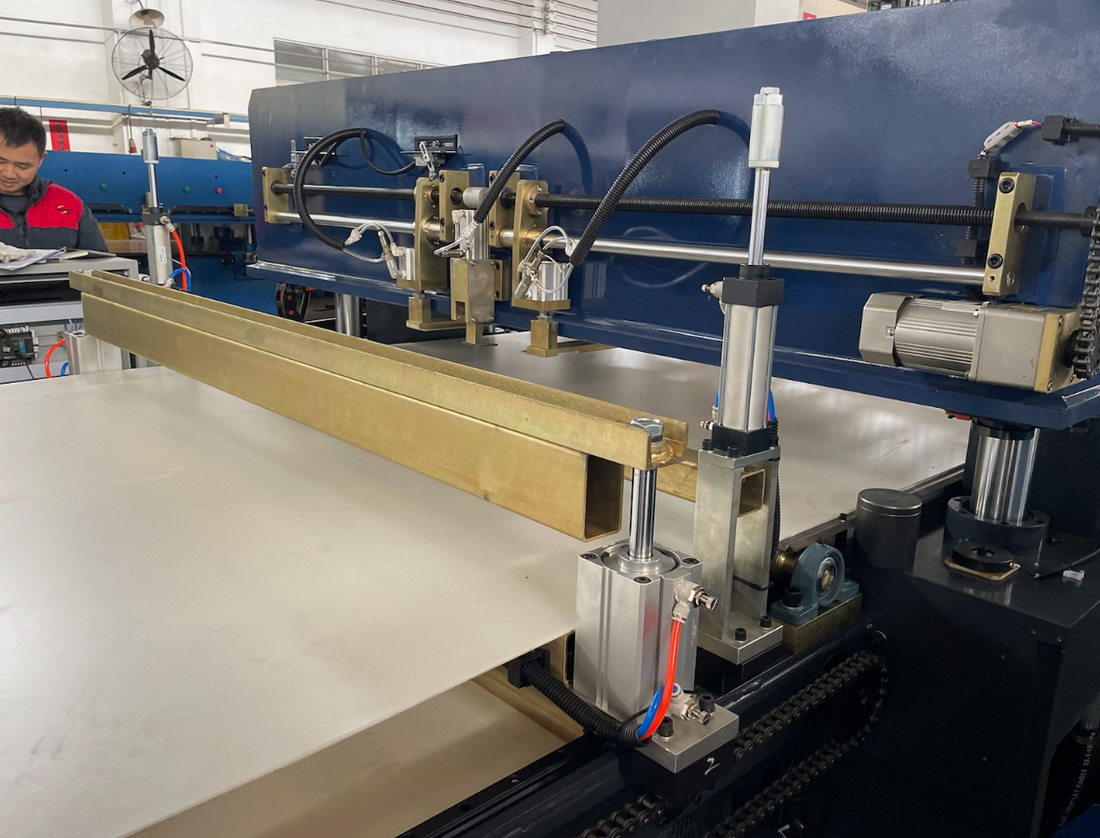

HydroBeam Manual Full Beam Press

Hydraulic Full Beam Press w/ Manual Push Table

The HydroBeam Full Beam Press is our best solution for large format die cutting operations. With cutting tables up to 72" wide and 60" deep, it is a favorite among fabric, leather, gasket, automotive, and aerospace manufacturers. We’ve combined a twin-cylinder hydraulic system with our Equalink deflection management system to produce high repeatability and cutting accuracies up to ±0.01".

This model only requires manually pushing table into and pulling the table out of the cutting position. The manually activating the cut by pushing the two operation buttons simultaneously.

Features

• 10" HMI touch screen

• Encoder-based depth setting (Macro-adjustment)

• Timer-based cutting depth (Micro-adjustment)

• Compression counter & hour counter

• JIC hydraulic fittings

• Safety light curtains & caging

• Recipe-saving technology

• Two handle/button operation with anti-tiedown and anti-double-click functionality

• Soft starter to balance startup amperage & increase energy efficiency

• Thermal overload protection

• Phase monitoring & over-voltage protection

Upgrades

• NRTL Intertek machine certification

• UL 508(a) electrical panel certification

• 3 Year Extended Warranty

• Dwell under pressure functionality

• Allen Bradley Swap

Options

+ Upper Heated Platen (0-400° F)

+ Lower Heated Platen (0-400° F)

+ Pick-and-Place

+ Blanking Screws