News

Competitive Benefits of Die Cutting

Competitive Benefits of Die Cutting

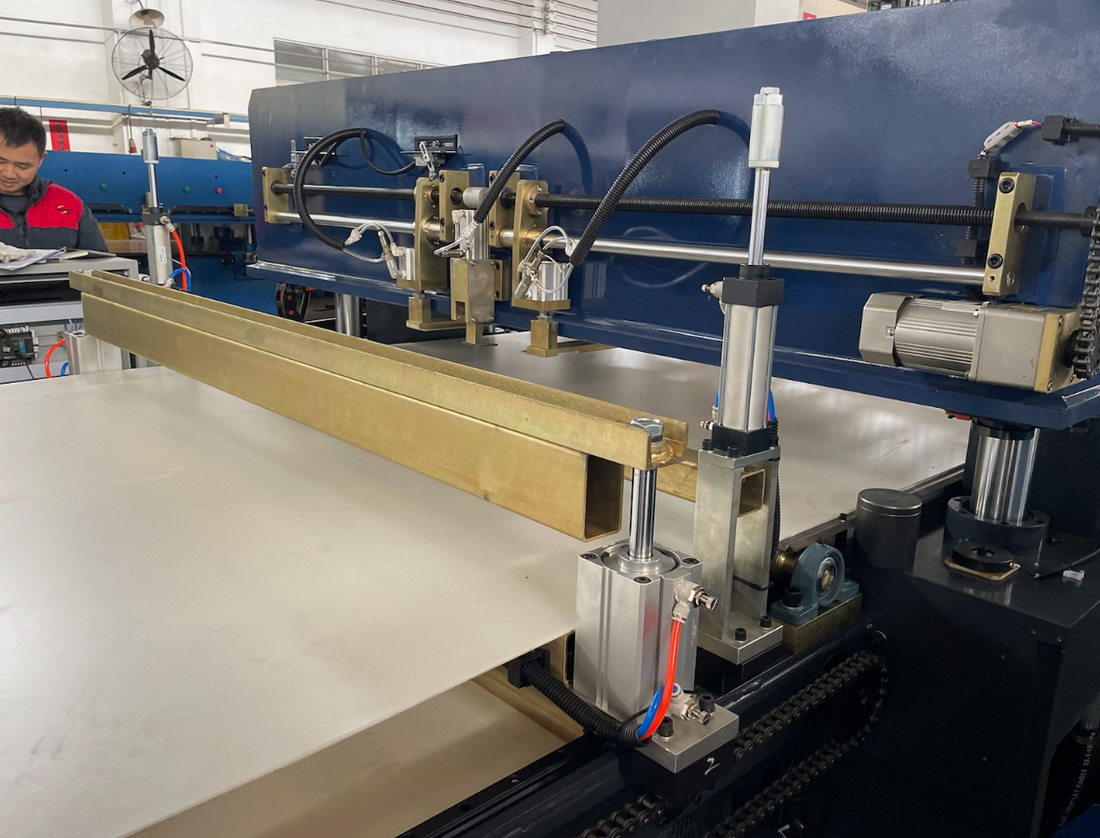

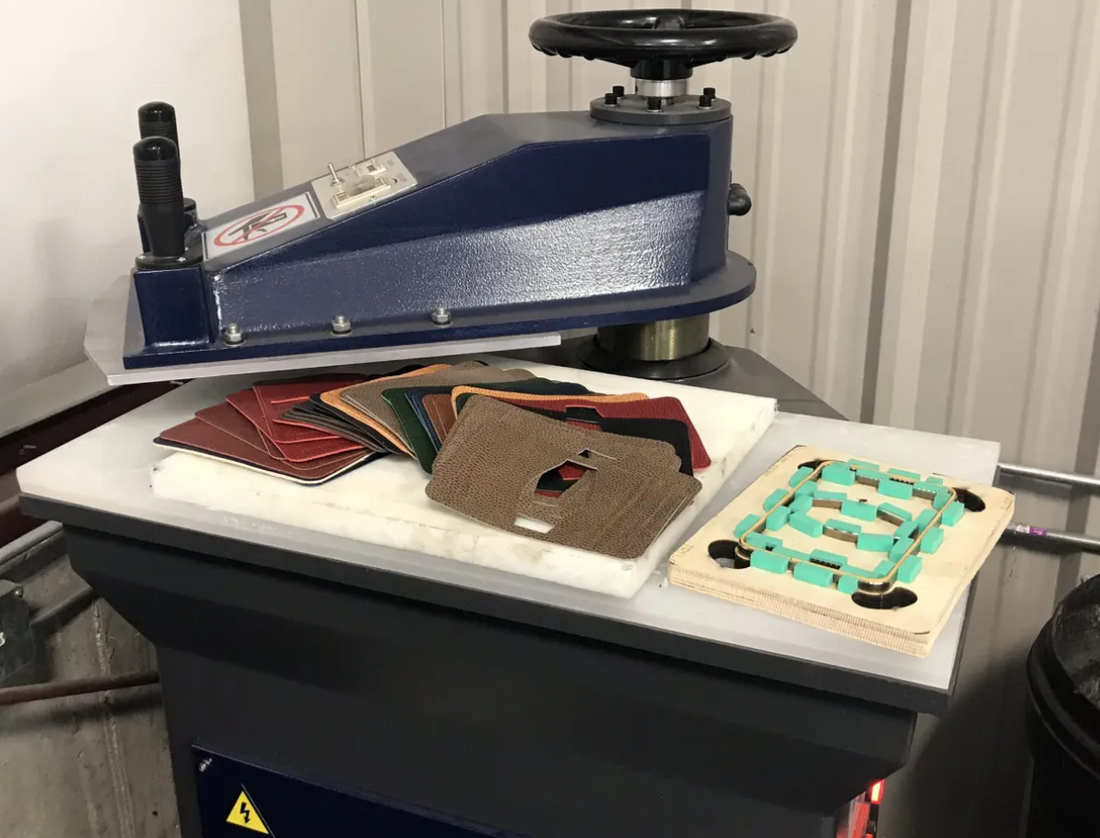

Die cutting is a versatile and cost-effective manufacturing process that has many benefits compared to other methods. It is used to cut and shape a variety of materials, including paper, cardboard, plastics, and non-woven fabrics, into precise shapes and designs.

-

Precision: Die cutting provides a high degree of precision, producing consistent and accurate cuts every time. This is especially important for manufacturers who require precise shapes and designs for their products.

-

Cost-effectiveness: Die cutting is a cost-effective method, especially when compared to other cutting methods such as laser cutting or waterjet cutting. It also has lower tooling costs and can be performed at high speeds, reducing production times and costs.

-

Versatility: Die cutting can be used to produce a wide range of products, from simple shapes to complex designs. It is also suitable for a variety of materials, making it a versatile manufacturing process.

-

Ease of use: Die cutting machines are relatively easy to operate and can be set up quickly, reducing production downtime. They also have a low learning curve, making it easy for new operators to quickly become proficient in their use.

-

Environmentally friendly: Die cutting generates minimal waste and produces little to no hazardous material, making it an environmentally friendly manufacturing process. This is especially important for manufacturers who are looking to reduce their carbon footprint and become more environmentally responsible.

-

Consistent quality: Die cutting provides consistent quality cuts every time, reducing the risk of defects and improving the overall quality of the finished product. This is especially important for manufacturers who require high-quality products for their customers.

Die cutting is a versatile, cost-effective, and environmentally friendly manufacturing process that provides a high degree of precision and consistent quality. Compared to other methods, it is an excellent choice for manufacturers who require precise cuts and designs, while reducing production times and costs.