News

The Best of Both Worlds: High-Quality Die Cutting Machines at Competitive Prices

The Best of Both Worlds: High-Quality Die Cutting Machines at Competitive Prices

In today’s competitive manufacturing environment, finding industrial machinery that balances quality and cost can feel like an impossible task. Many U.S. manufacturers face a difficult choice: invest in expensive, domestically produced machines that boast high durability and reliability, or opt for cheaper, imported alternatives that too often compromise on performance, safety, and longevity.

At Hammerhead Industrial, we understand this dilemma all too well. We’ve built our entire business model around solving this problem, offering U.S.-designed, quality-controlled machines at prices that make sense for small to mid-sized manufacturers. This blog explores how Hammerhead Industrial provides a solution that blends the best of both worlds — high-quality machines with competitive price points — without sacrificing performance, durability, or safety.

The Cost vs. Quality Dilemma: Understanding the Challenge

Manufacturers in the U.S. have long grappled with the trade-off between purchasing machines that are affordable and those that are built to last. The conventional wisdom is that if you want durable, high-performing machines, you must buy American-made equipment, which tends to come with a hefty price tag. On the other hand, opting for cheaper, mass-produced machinery from overseas, typically from China, often leads to issues with quality control, shorter product lifespans, and frequent breakdowns.

While low-cost machines might meet initial budget constraints, their lack of reliability can create serious problems down the road — from costly repairs and replacement parts to unplanned downtime and reduced productivity. And let’s not forget the frustration and loss of time that comes with trying to get support or replacement parts for a poorly performing machine. These hidden costs can quickly outstrip the savings manufacturers thought they were securing by choosing a cheaper alternative.

A Hybrid Approach: Why Hammerhead Industrial is Different

This is where Hammerhead Industrial comes in. We recognized early on that the needs of small and mid-sized manufacturers were being ignored by much of the industry. Too many companies were forced to either overspend on premium U.S.-made machines or gamble on unreliable, low-cost imports. We set out to create a new, hybrid approach that offers high-quality machines without the high price tag.

Here’s how we do it:

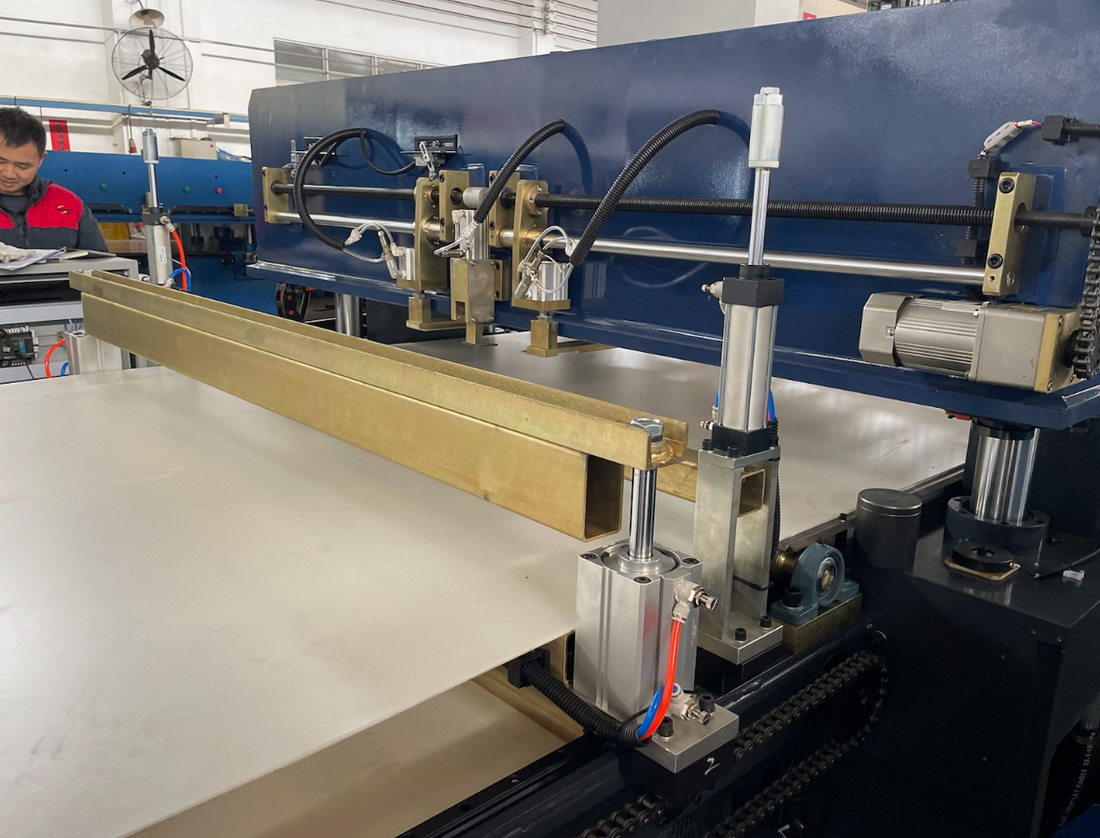

- U.S.-Led Design: We start by doing the majority of our design work here in the U.S., ensuring that our machines meet the unique needs of American manufacturers. This allows us to integrate the latest innovations in machine safety, customization, and operational efficiency.

- Global Manufacturing: To keep our prices competitive, we partner with trusted manufacturers in China to produce the core components of our machines. This global sourcing allows us to take advantage of cost efficiencies without compromising on quality. We ensure that every machine meets our strict design specifications.

- Quality Control Done Right: What sets us apart from the competition is our rigorous quality control process. Once the machines arrive at our U.S. facilities, we don’t just ship them straight to customers. Instead, we take the time to thoroughly inspect and test each machine. We make necessary improvements, offer customizations, and ensure that everything is up to our high safety and performance standards before a machine leaves our floor.

Meeting the Cost Goals of U.S. Manufacturers

At Hammerhead Industrial, we know that manufacturers of all sizes need to meet tight cost goals, especially in today’s uncertain economic environment. The pressure to control costs is particularly acute for small and mid-sized businesses that may not have the same financial flexibility as larger corporations. That’s why we’ve structured our business model to offer machines that meet the needs of these companies without asking them to break the bank.

Our hybrid approach delivers key advantages:

- Reduced Capital Expenditure: By sourcing from China while maintaining U.S. quality control, we can offer machines at prices significantly lower than fully U.S.-made counterparts. This means lower upfront costs for manufacturers.

- Long-Term Reliability: Despite the lower cost, our machines are designed and inspected to ensure long-term durability and minimal downtime. This translates into lower maintenance costs over the machine’s life.

- Flexibility for Growth: By providing high-quality machines at competitive prices, we give our customers the flexibility to grow their operations. Instead of putting all their capital into a few expensive machines, they can purchase the equipment they need to expand, knowing that their investment will last.

Avoiding the Pitfalls of Cheap Imports

Some of our competitors focus solely on price, offering the cheapest machines available. While this may seem attractive at first glance, the long-term implications of buying poorly made equipment can be devastating. We’ve seen firsthand the problems that arise from machines that are produced with little to no quality control. Common issues include:

- Frequent Breakdowns: Cheap machines are often made with inferior materials and components, leading to frequent mechanical failures. These breakdowns can cause unplanned downtime, affecting your production schedule and your bottom line.

- Lack of Support: Many low-cost machine providers offer minimal customer service and support. When something goes wrong, you may be left with few options to fix the issue, often forcing you to invest in costly repairs or replacements.

- Safety Risks: Cheap machines often fail to meet important safety standards. This can put your workers at risk and lead to compliance issues with regulatory bodies such as OSHA.

Hammerhead Industrial is committed to avoiding these pitfalls. Our machines are not only competitively priced but are also built with longevity, reliability, and safety in mind. Every machine we sell has been rigorously inspected and tested, ensuring it meets the highest standards of quality.

Customization Without Sacrificing Affordability

One of the key benefits of choosing Hammerhead Industrial is the ability to customize our machines to meet your specific needs. Unlike many low-cost providers who offer only off-the-shelf solutions, we recognize that every manufacturing operation is different. Whether you need custom cutting tools, unique machine configurations, or specialized safety features, we can tailor our machines to your exact specifications.

Our ability to customize machines is another reason why our equipment represents such a strong value for U.S. manufacturers. Instead of settling for a machine that only partially meets your needs, you can work with us to create a solution that fits your business perfectly — all while staying within your budget.

How Quality and Cost Go Hand-in-Hand at Hammerhead Industrial

For too long, the industrial machinery market has forced manufacturers to make impossible choices between quality and cost. But at Hammerhead Industrial, we believe you shouldn’t have to sacrifice one for the other. Our hybrid approach allows us to provide high-quality, durable, and customizable machines at price points that make sense for small and mid-sized manufacturers.

- Quality-Controlled in the USA: By handling design and quality control in the U.S., we ensure that our machines meet the highest standards of safety, reliability, and performance.

- Affordable Global Sourcing: Our partnerships with trusted international manufacturers allow us to offer competitive prices without sacrificing the features and innovations U.S. manufacturers need.

- Long-Term Value: With our machines, you get not only upfront savings but also long-term value. Our equipment is built to last, helping you avoid the hidden costs of breakdowns, downtime, and repairs.

Conclusion: The Smart Choice for U.S. Manufacturers

At Hammerhead Industrial, we’re proud to offer the best of both worlds: high-quality, customizable machines at prices that meet the needs of small and mid-sized U.S. manufacturers. Whether you’re looking to upgrade your equipment, expand your operations, or simply find a more reliable alternative to the low-cost imports flooding the market, we’re here to help.

By choosing Hammerhead Industrial, you’re not just purchasing a machine — you’re making an investment in your company’s future. With our commitment to quality, customization, and competitive pricing, we’re confident that we can help you achieve your production goals without compromising on performance or breaking your budget.

By Joseph Perry