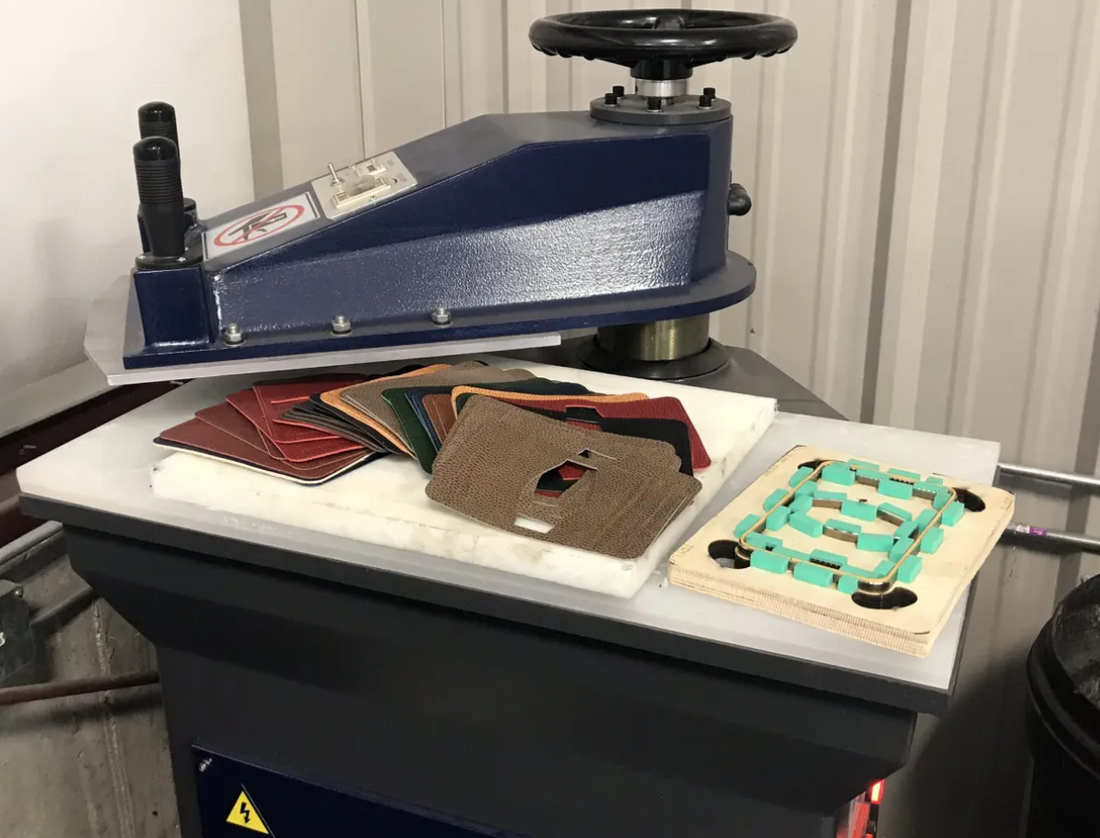

Die Cutting, Embossing, and Converting Essentials

Explore our best-selling Machines

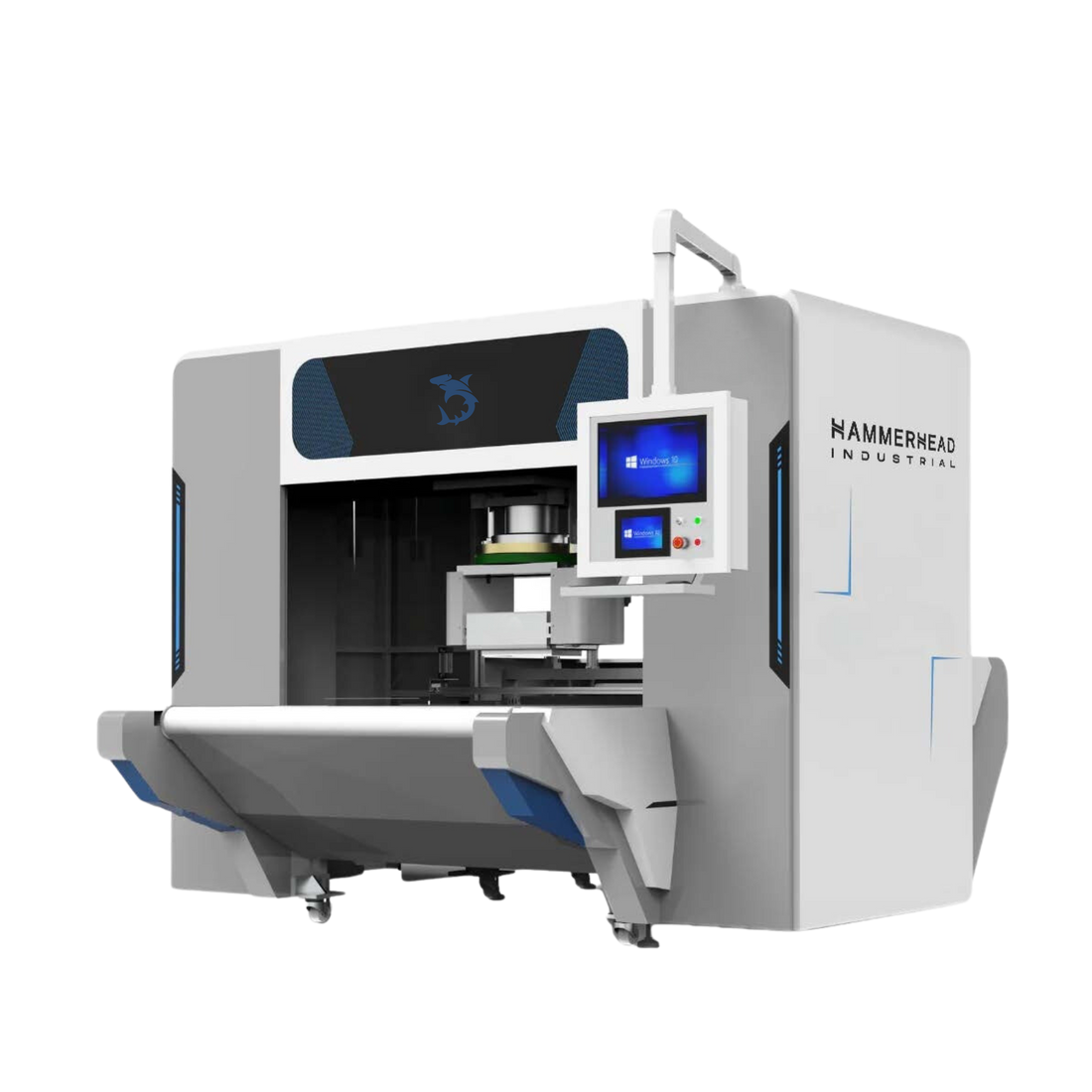

What makes it a

HAMMERHEAD MACHINE?

Hammerhead Industrial focuses on what brings value to our customers. Intuitive controls, long-lasting components, a robust machine body, and a look that matches your vision for your own company.

Intuitive Touch

Screen Controls

Intuitive Touch

Screen Controls

Our intuitive touch-screen and user interfaces provide a clear process for setup and operation of the machine, ensuring that the machines can be run by user of all capability levels. Our interfaces usually include some or all of the following:

- Operational Interface Screen (with live job progress monitoring)

- Compression History Log Screen

- Recipe Saving and Calling Screen

- Step-by-step Setup Pages (for job setup and setting of cutting and rising heights, dwell times, and other parameters)

- Diagnostic Page(s) (for live I/O readouts)

- Advanced Settings Page

- Factory Settings Page (password protected)

The Newest Technology

The Newest Technology

Hammerhead Industrial is insatiably designing, discovering, and iterating on new machine capabilities. Ask us about our newest options:

- Multi-Die Traveling Heads (2 or 4-sided flip)

- Automatic Tool Exchange with Tool Garages

- Intelligent CNC Nesting Software with Tool Scanning Stations

- Intelligent Vision Options (for tool alignment)

- Intelligent AI-mapping (for no setup cutting and trimming)

- Job Barcode Scanning (scan barcode on die or mold to import job parameters automatically)

- Ask us about your other custom requirements

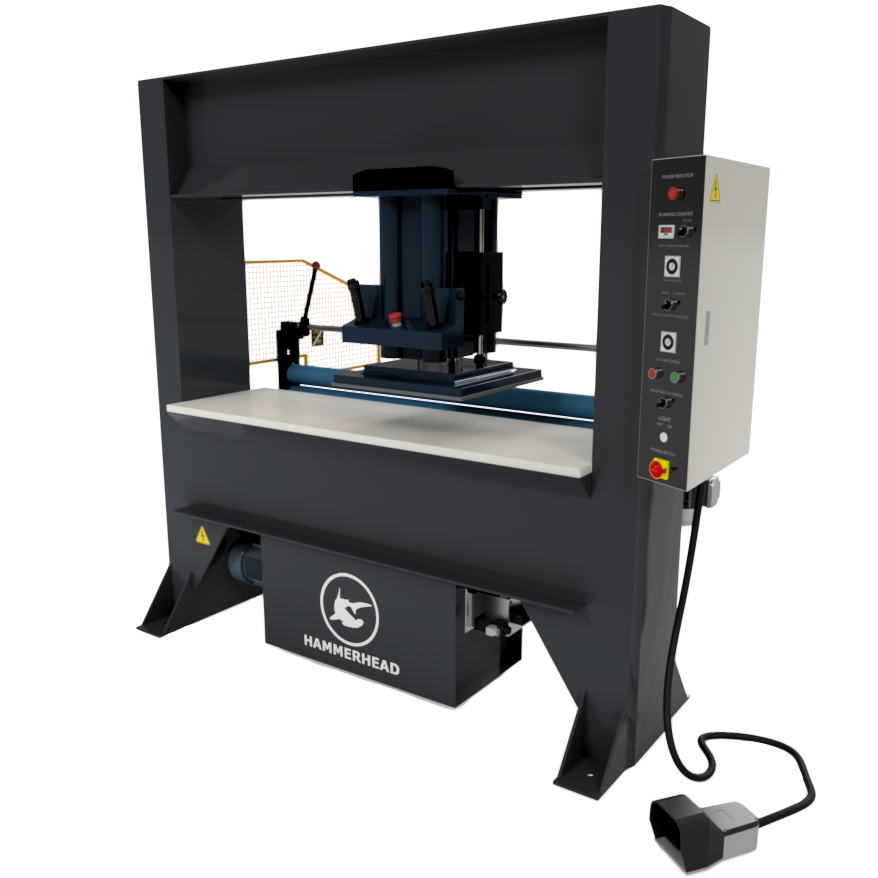

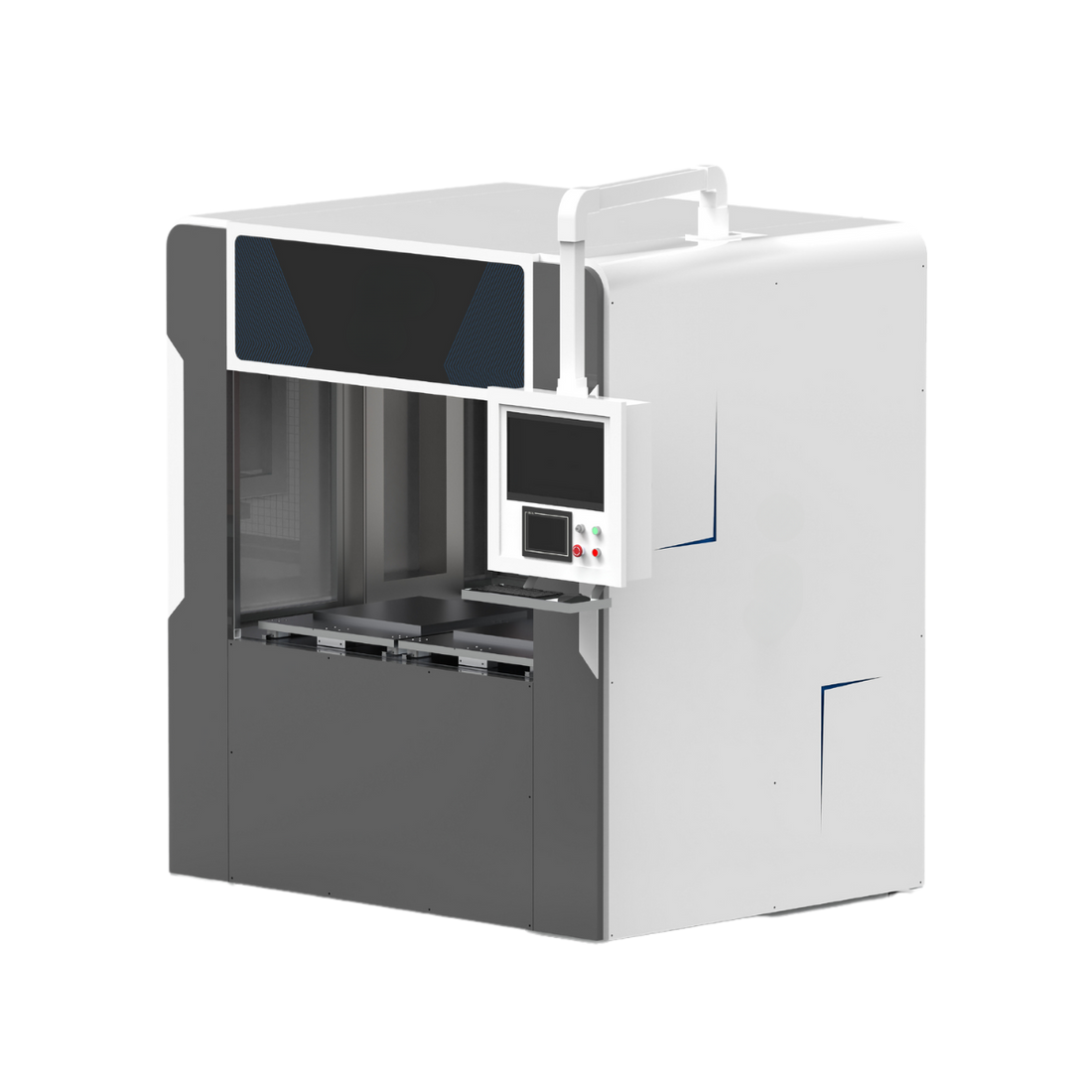

Clean Body Design

Clean Body Design

Our machine designs are great to look at, but they serve some great purposes alongside bringing the designs into the modern age:

- The improved designs for our machine bodies upgrades physical guarding needed to comply with more safety regulations

- The machine body makes it easier to provided coverage with electrical safety devices, scanners, and light-curtains, by mounting them inside the guarding, and caged-door access areas

- The newest designs have designated areas within safely protected areas to mount cameras, tool exchangers, and many other innovative new systems that Hammerhead Industrial is developing

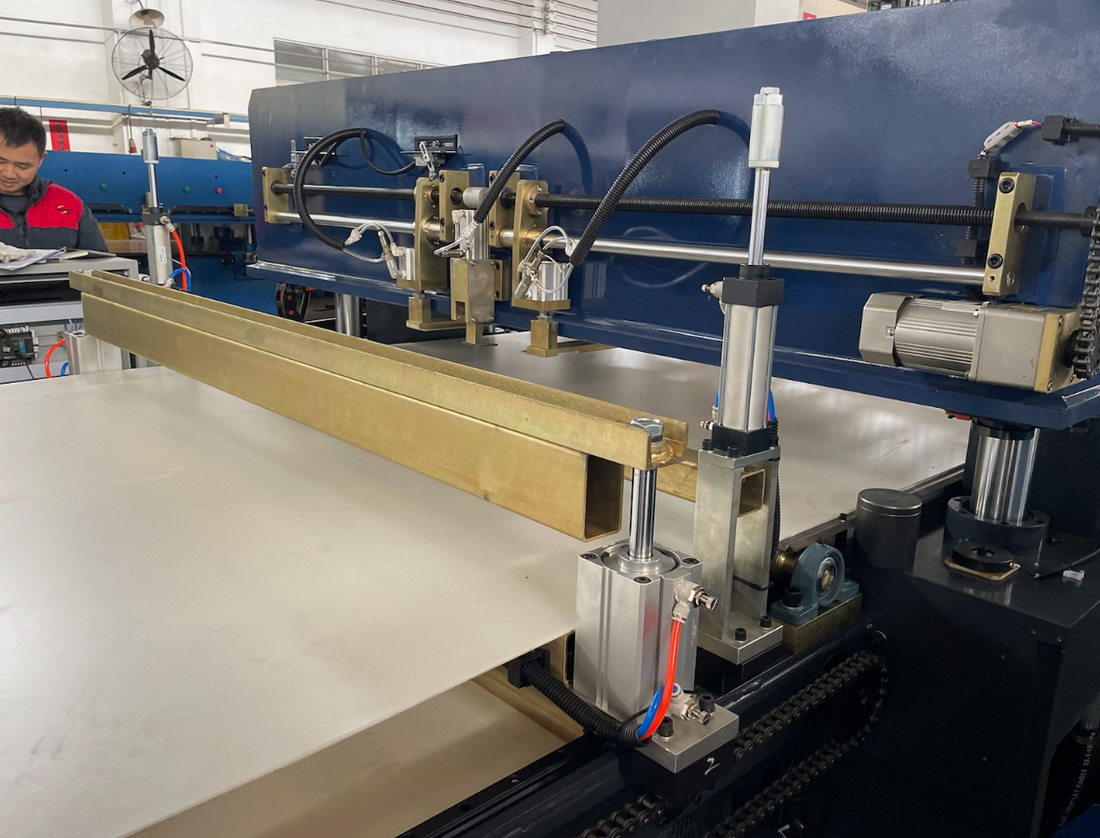

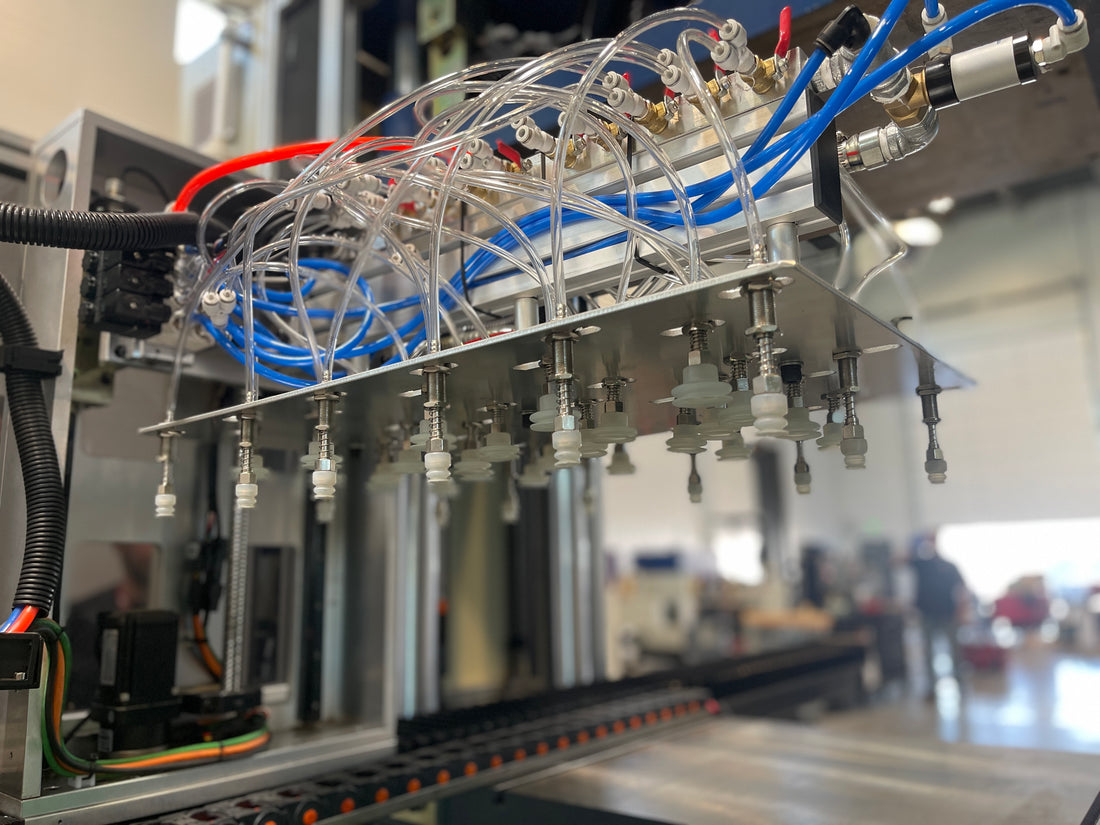

Top-level automation

Top-level automation

We can take care of all of your automation and integration needs. We do our own integration work so that the hand-off between your materials and our machine is flawless every time. We can expertly design and integrate the following:

- Pick-and-Place Gantry-Style Robotics

- Fanuc Robotics

- Conveyor Belt Feeding Automation

- Pinch Roll Feeding Automation

- Motorized Table & Dual Motorized Table Feeding

- Lip-edge Feeding Systems

- Foam Sheet Gravity Feeding, Blocking, Laminating

- In-line Lamination

- Heated Platens and Attachments

- Intelligent Vision & Registration

- Custom Requirements

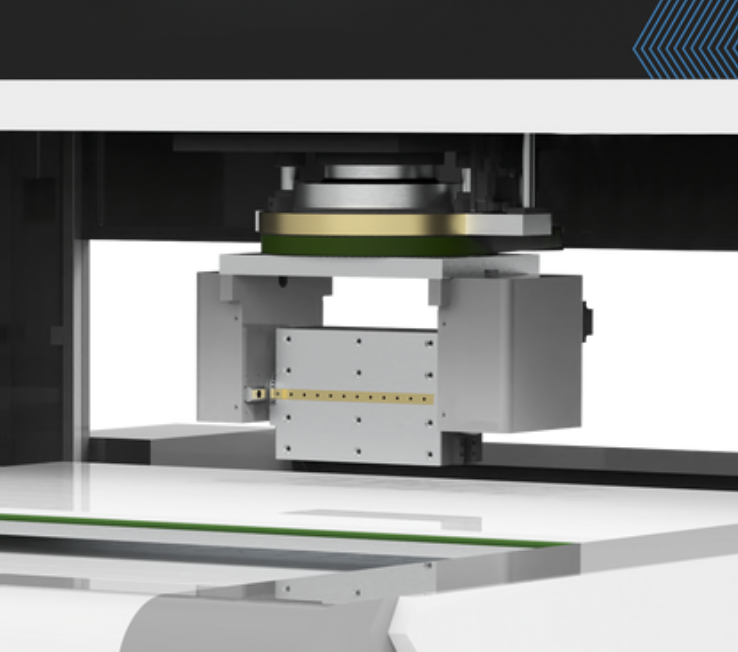

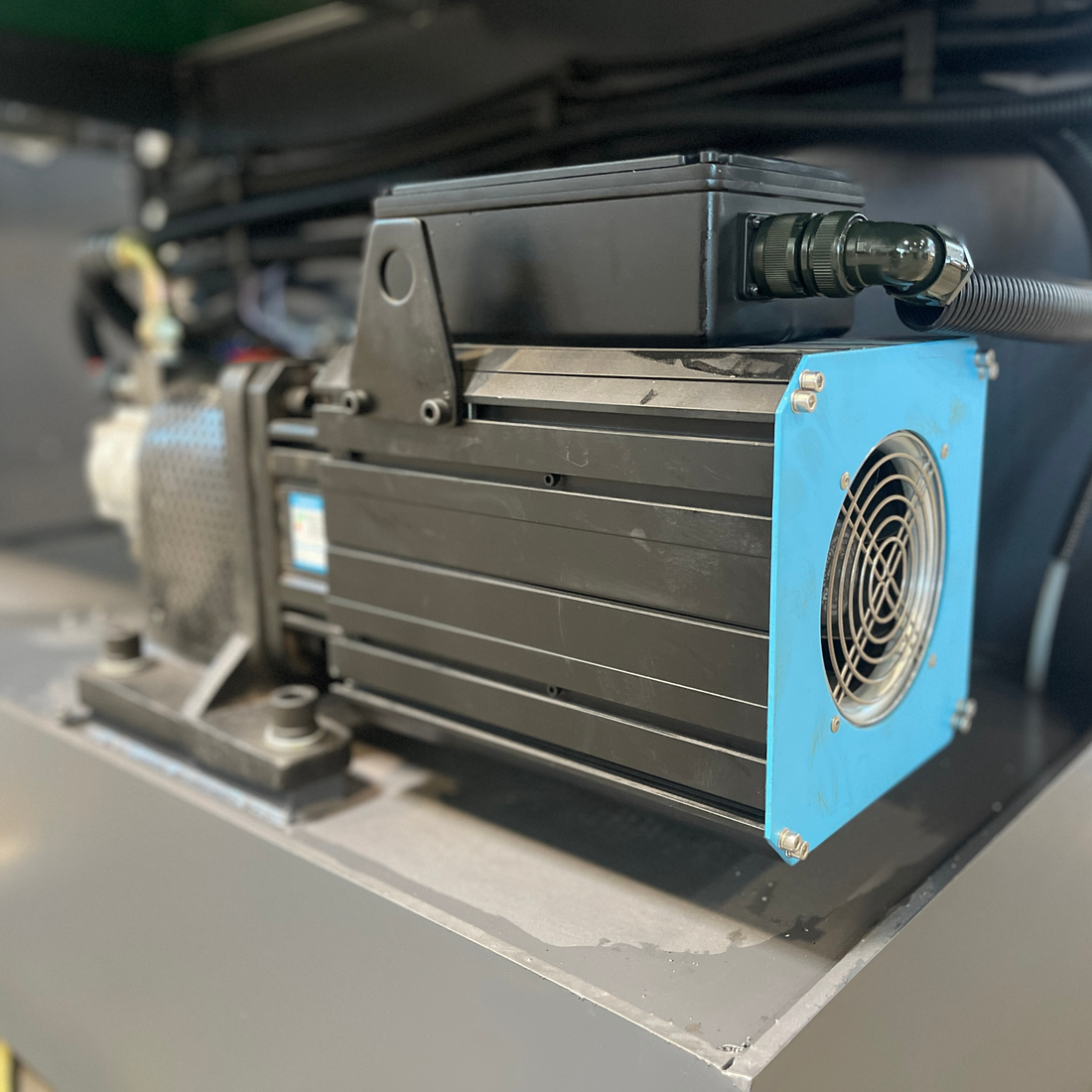

Industry-leading

Servo-Electric

Technology

Industry-leading

Servo-Electric

Technology

Many of our machines come in servo-electric or servo-over-hydraulic models. Fully servo driven machines can increase energy efficiency by over 50%, reduce noise by more than 70%, and typically improve cutting accuracy by 50%. These machines are great for the following industries:

- Medical Cleanroom

- Electronics Cleanroom

- Pharmaceutical Cleanroom

- Food Packaging

- Food Production

- Noise-Sensitive Environments

- Pressure Sensitive Applications

- Other Sensitive or Cleanroom Applications

Industry-Leading

Safety Standards

Industry-Leading

Safety Standards

Hammerhead Industrial is leading the way by strategically partnering with the leaders in safety equipment. We partner with Keyence and other leading companies to provide a robust set of safety upgrades to our machines including:

- Safety Controllers

- Safety Relays

- Safety Light Curtains

- Safety Laser (Area) Scanners

- Safety Interlock Switches

- Safety Enclosures & Caging

- Lockouts and Password protected machine settings

- Custom alarms

- Pressure-Sensitive Operator Mats

No One Can Beat

Our Follow Through

"We bought a mini beam press configured with a 110v conversion approximately 4 years ago. It worked flawlessly until it didn’t. I gave Joseph a call and in 2 days a tech showed up at our door to fix the problem. The tech worked all day but unfortunately the problem couldn’t be resolved with the parts he brought and he replaced just about everything. So he left and Joseph showed up the next day. Reconfigured the press to 220v, replaced another part and even wired the location to accept 220v. These guys went beyond “way beyond and above” to help out a small company that bought the least expensive press they had over 4 years ago. This is the kind of service you only hear your grandfather talk about. This is service I wont forget anytime soon. I can’t recommend these guys enough."

Gary Lader

Mat Depot

Customer Service is priority, and it shows through every facet of this business. We ordered a 20 ton swing arm, with the expectation of delays due to Covid. We were continuously updated on the progress of our order, and never once was concerned as to the time frame of delivery. Press was shipped, and at some point in transit was damaged (things happen right). Upon arrival to our shop, the damage was discovered, and Joseph was contacted to be made aware of the issue. From there, we were able to truly experience who HAMMERHEAD is. Joseph had a solution in place within the hour, with a new press being framed and crated within the day. The 20 ton press we ordered was out of stock, and Joseph promptly made the decision to upgrade the press to a 25 ton press. Within a few days, we had the new press delivered, and placed in service same day. As far as the machine goes; we've only logged about 12 hours on it. Set up was as expected, and was completed within a couple hours (Electrical, Oil). The machine seems very well built, and operates as expected. Thank you to Joseph and team for a very positive experience, and treating our small business like family!

Courtney & Spencer

Axe and Awl Leatherworks

"Excellent sales and shipping support! I received my 25 ton clicker press yesterday. I was amazed at the expeditious lead time! Upon arrival, we got it up and running with the easy to follow instillation instructions and within a very casual 30 minutes, one operator had out performed what would have taken over 12 man hours to accomplish the same task by hand! It’s my new favorite machine in the workshop and I honestly don’t know why I didn’t invest in one of these suckers sooner! By my projections this beast will pay for itself In less than 3 months! Probably much sooner once we establish a more efficient workflow! The folks that count the beans will be very happy to hear that! I can't glow enough about the customer service! Very fast, if not immediate responses to inquiries. This company is an absolute delight to work with. Too bad I can't give them six stars, or ten for that matter!"

Jackson Douglas

Ben Orson Apparel, LLC

"After running a pneumatic press for over a year, I was ready to step up to the big leagues. I found HAMMERHEAD after a quick google search, perused their website and was immediately impressed with one thing: transparency. They had pricing listed right there on the site. Most places that deal in equipment like this won’t show even base pricing publicly, they want you to call, give you the run around and try and milk you with extended warranty this, premium package that... HAMMERHEAD is up front and open and helps you out every step of the way! Joseph even arranged shipping straight to my residential location and answered any question I had extremely promptly. These fellas are top-notch. Next time I’m in the market for a press, I’m not even going to shop around, it’s straight to HAMMERHEAD for me!"

Lee Mason

Mason Leather

"Great Experience. We just took delivery of a CS-750 clamshell press from HAMMERHEAD. From the order to delivery, Joseph kept me up to date on the status of the shipment. He had training videos created to get us up to speed immediately. The press was tested thoroughly prior to delivery, and it arrived ready to power up and go to work. Being new to this type of die press, I had a lot of operational questions, but Joseph and his team provided answers immediately. I highly recommend HAMMERHEAD."

Craig Szelestey

C2 Imaging

“If I could leave two 5 star reviews I would. One for customer service and one for the product itself. I have never had better customer service from any company in any industry. They could open a side business just doing customer service training for other companies. When we were trying to decide what machine we would need for our business they actually let us send in our dies and material. They then did a few test on different machines and actually steered us to the most inexpensive machine they have. This would have been a perfect opportunity to sell us on something more expensive, but no. They put us with the machine that would get the job done. And it really does get the job done. We have had the 10 Ton swing arm press for almost a year now. So far we have done a little over 100,000 punches with it and have absolutely zero issues. It just works like it’s supposed to. The industry we are in exploded during quarantine and has not slowed down at all. The only way we were able to keep up is this machine. Without it we would have had to stop taking orders, which is not a very good business plan. Honestly this machine bought our new house. We really owe a big thanks to Joseph and the rest of the team. We would not have been able to grow like we did without them.”

Jonathan Elliot

Rollerstuff

OUR CORE VALUES

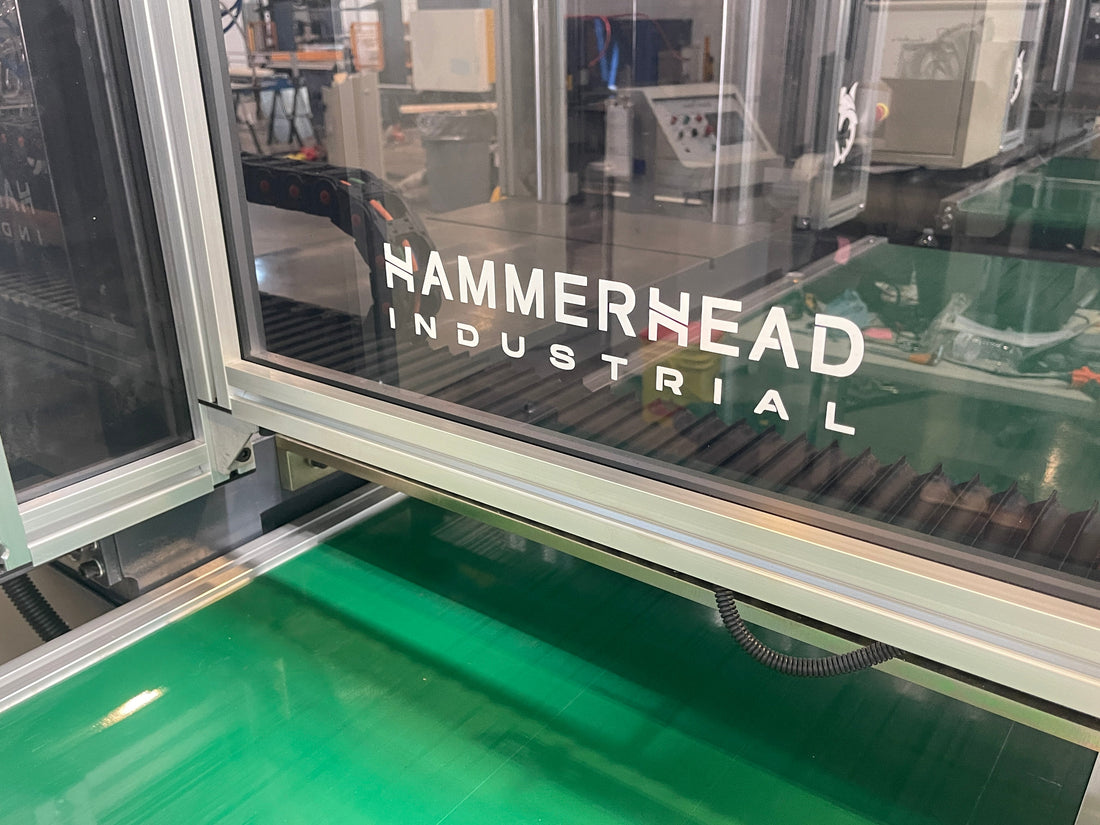

Machine Design Gallery

Featured blog posts